Plastic Recycling Equipment-PET Crusher

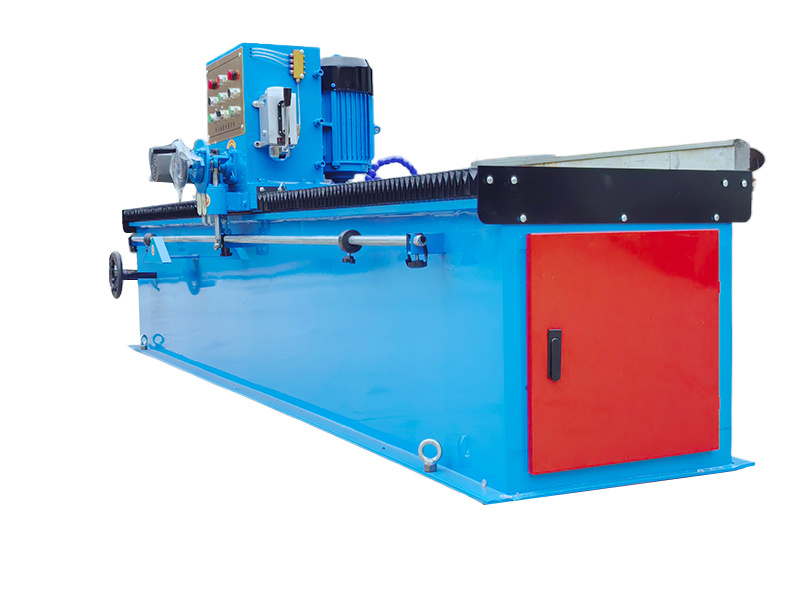

De-labeling machine

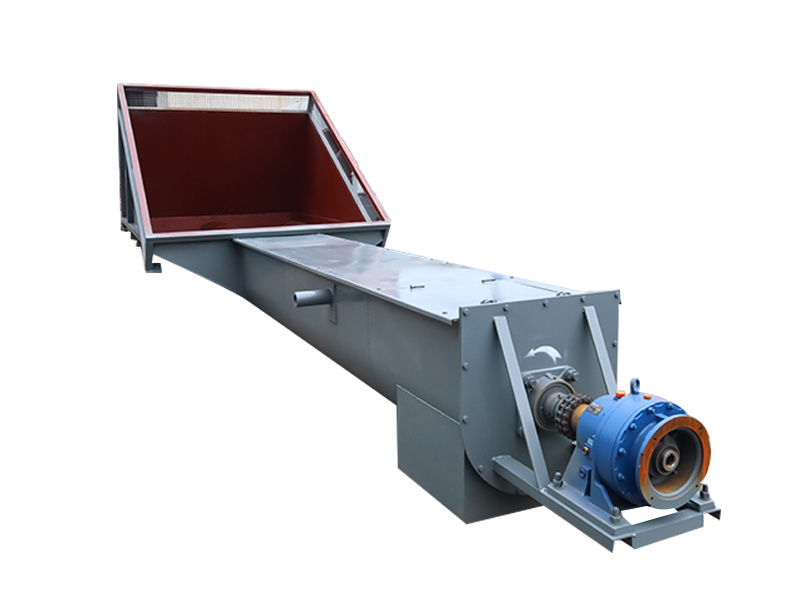

All net dumping machine

Opener charter

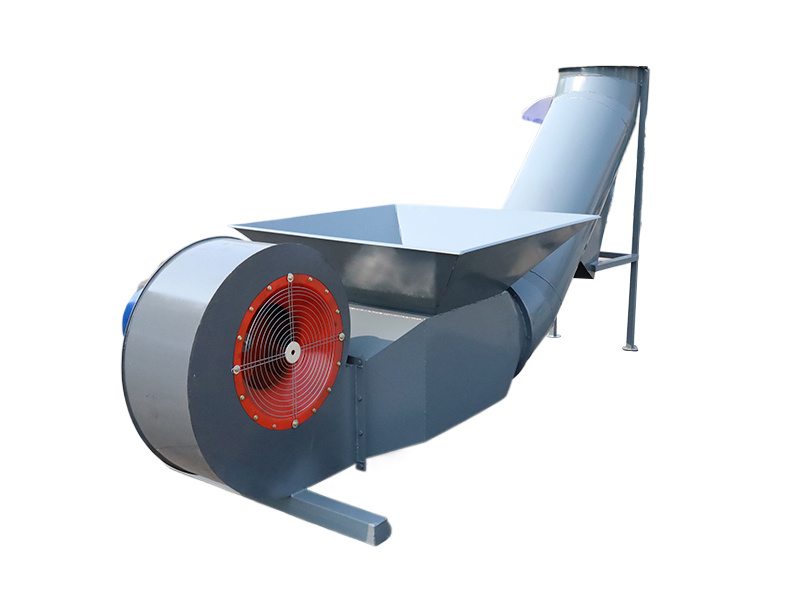

Wind separator

Rinsing tank

Ton Packer

Bouncing screen

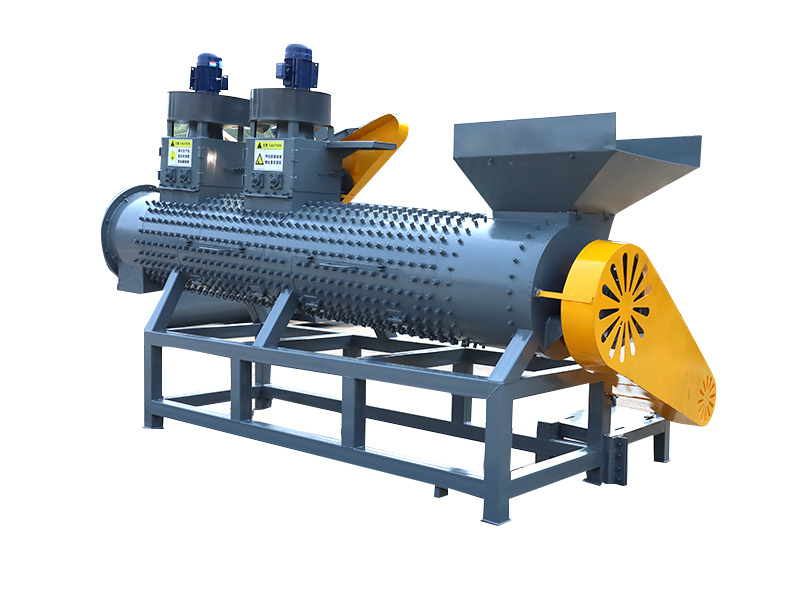

Whole bottle washing machine

Vibrating screen

PRODUCTS

Choose from Our Range of Products

Main Products: Pet bottle brick cleaning and recycling line,Pet bottle cleaning and recycling lin,High-end hot washing on machine linefor huayi daxiaobai, etc

Pioneer machine building Pioneer machine building Pioneer machine building Pioneer machine building

TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS

TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS

ABOUT US

Professional plastic recycling equipment manufacturing

Shunping Xianfeng Machinery Manufacturing Co., Ltd. is an enterprise specializing in the production of plastic cleaning and recycling equipment integrating research and development, design, manufacturing and sales. The company was founded in 1984, covers an area of 35,000 square meters, has a standard production plant 18000 square meters, for many domestic and foreign outstanding enterprises to provide high-quality plastic recycling solutions.

Exporting countries and regions

Covers an area of 35,000 square meters

Exporting countries and regions

18

years of industry experience

To provide you with a full range of solutions

CUSTOMIZED

PET bottle brick cleaning and recycling line

The cleaning process is divided into unpacking, removing impurities, pre-washing the whole bottle, de-labeling, sorting, removing metal, crushing, sinking and floating separation, hot washing, friction, bleaching, dehydration, de-labeling and packaging processing sections

The output can reach 1000KG-8000KG per hour

Products can be directly used for blowing, injection molding, drawing and other processes, without cleaning again.

We have many years of export experience and sold to more than 30 countries.

Our Capabilities

For many domestic and foreign excellent enterprises to provide high-quality plastic recycling solutions. mu

Quality Control

To ensure the quality of product materials, consistently set high standards for every goal and pay attention to every detail.

Innovation

The company has set up a team of high caliber inter disciplinary talents to research core technologies keep releasing energy in production.

BLOG

News & Media

Feb 24,2025

Working principle of heating tank

Feb 24,2025

Feb 24,2025

Working principle of heating tank

Feb 24,2025